It has almost been eight years since the establishment of Darma Tech Labs in August 2015, the predecessor of Monozukuri Ventures (MZV). As our fiscal year closes in March, we kicked off our ninth fiscal year this April. Recently, we had the opportunity to discuss the future direction of our company at our all-hands meeting.

In this blog post, I would like to share the journey of MZV thus far and our vision for the future.

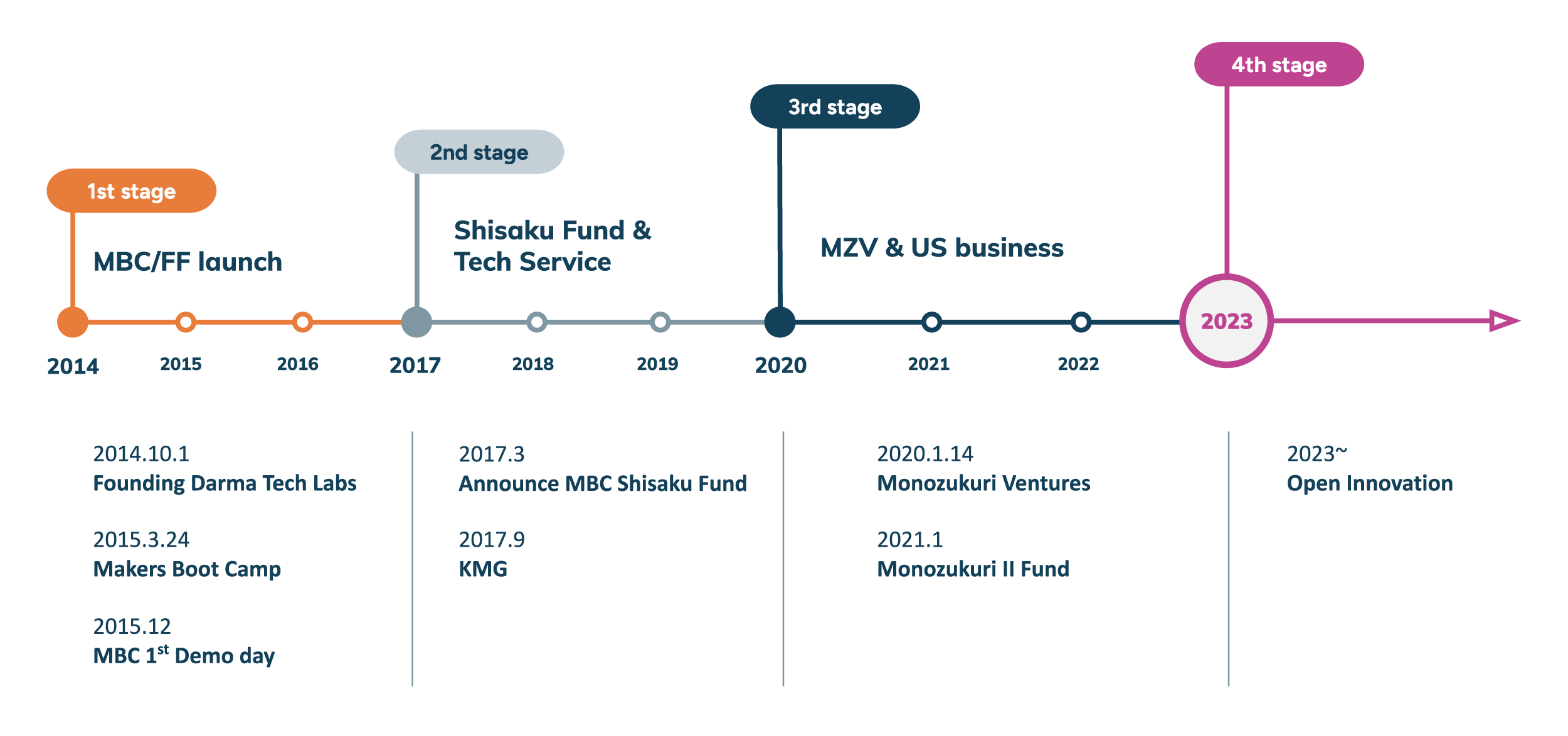

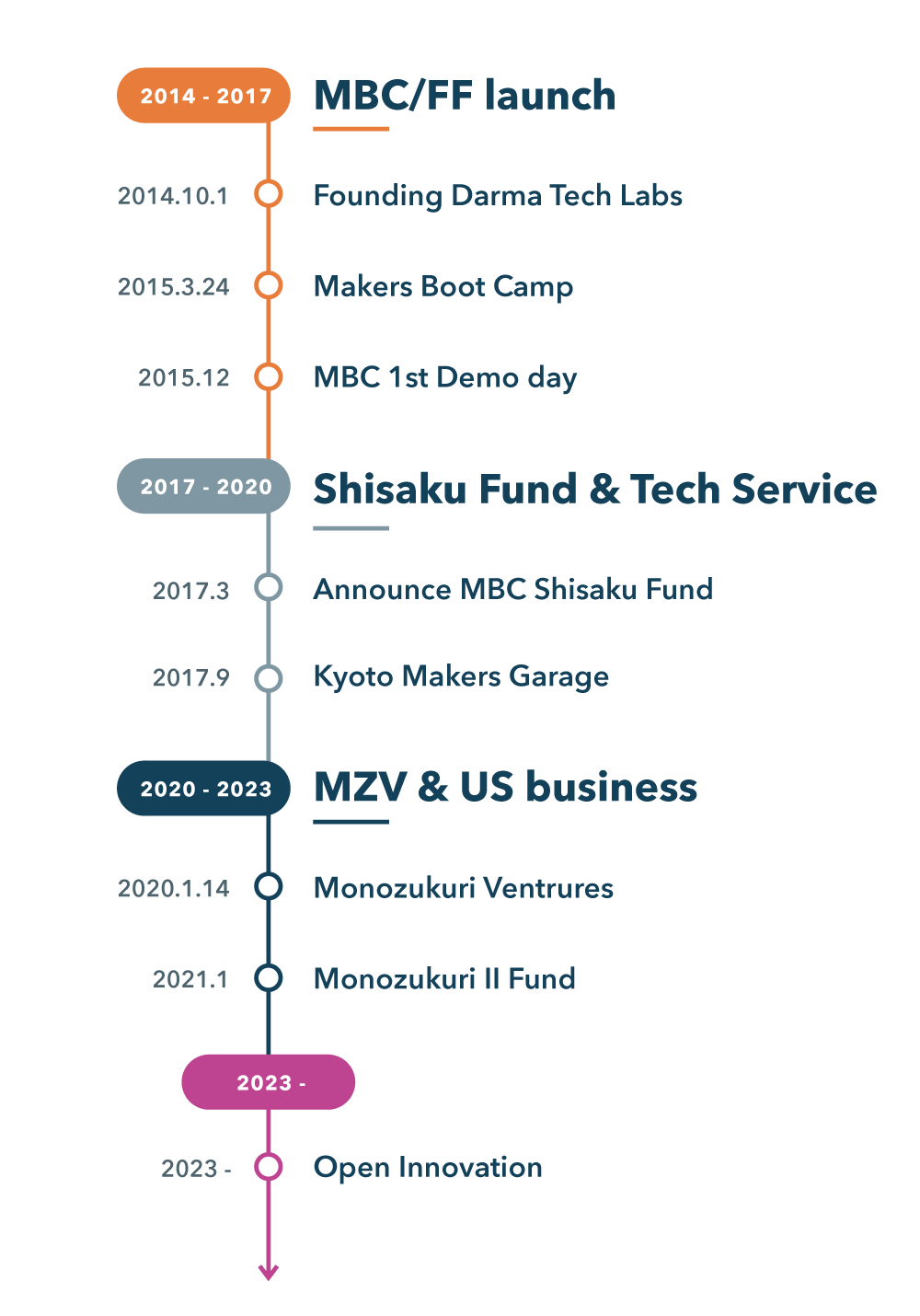

The Journey

1st Stage (2014-2017) – Launching Makers Boot Camp

Firstly, let’s touch upon the origin of Darma Tech Labs, the predecessor of Monozukuri Ventures. Around 2010, due to the maker movement, there was a surge in hardware and IoT startups. Yet, it was apparent that these hardware startups were struggling with scaling up, particularly with design for mass production. Furthermore, having started my venture capital (VC) career in the Kansai/Kyoto region, I have always been firmly committed to supporting startups in the Kansai area.

Amid these circumstances, I realized that if we could couple the startups’ mass production issues with the manufacturing industry’s strengths – one of Kansai’s core competencies – we could become a globally competitive VC. We saw the potential of collaborating with Kyoto Prototype Network (Kyoto Shisaku Net), a group of prototype professionals in Kyoto. We discussed with them transforming Kyoto into a global hub for manufacturing startups. And with support from my coworkers at a VC I used to work for, we established Darma Tech Labs.

Founders of Darma Tech Labs in 2015. From left, Fujiwara (CEO of Hacarus), Makino, and Takeda(CEO of CrossEffect)

However, we didn’t have the funding to do VC at first. So, we decided to focus on providing services to address the startups’ issue – prototyping. This led us to develop the “Makers Boot Camp (MBC)” acceleration program. We launched the program where professionals from the manufacturing industry, mainly from the Kyoto Prototype Network, would lecture startups about their business and manufacturing challenges.

Six startups participated in the first iteration of this program, which we held weekly in Kyoto, starting in September 2015. However, we soon realized that the problems faced by each startup were unique, and it was more effective to tailor our services to meet the needs of each company. Although we did recruit for a second program, we ended up not hosting that, making the first iteration the last.

- In September 2015, Japan’s first hardware focused venture support program, ‘Makers Boot Camp,’ began, with an aim to learn prototyping for mass production. (August 2015)

- Companies mainly from Kyoto Shisaku Net invest in Darma Tech Labs that manages ‘Makers Boot Camp,’ to support hardware startups (December 2015)

2nd Stage (2017-2020) – Launch of Technical Services and Shisaku Fund

While running Makers Boot Camp (MBC), we noticed several gaps between startups and manufacturing companies, such as mindset, speed, and culture. We realized there were a lot of inefficiencies and saw a need to become an “interpreter” between the two sides. So, we hired individuals with experience in large manufacturing companies and set up a technical team in 2017. Initially, they had difficulty interacting with startups, but they’ve since become adept at solving startup challenges, being involved in more than 190 prototype and mass production projects as of March 2023. Several successful projects emerged during this period, including rapid mass production launches like Smart Shopping. In collaboration with Kyoto City, we also established “Kyoto Makers Garage,” where even people without manufacturing knowledge can quickly bring their ideas to life.

As startups we supported successfully moved on to mass production and securing funding, we realized responding quickly to their funding needs could further accelerate their growth. Thus, we decided to create a VC fund.

As a result, a very unique and globally rare venture fund that combines prototyping support and investment was born.

While it wasn’t easy, we managed to share our vision with some financial institutions, such as The Bank of Kyoto, and manufacturing companies like DMG Mori Co. In July 2017, we successfully launched the MBC Shisaku Fund (Fund I). By July 2018, we raised approximately 2 billion yen and invested in 34 startups, including 16 in Japan and 18 in the US.”

Press conference on the establishment of MBC Shisaku Fund in March 2017. From left , Nadaka (CEO of Nadaka Precision), Takeda (CEO of Cross Effect), Makino, and Naka (Executive Director of Kyoto Bank at the time)

- Makers Boot Camp, an accelerator specialized in hardware startups, has formed a fund of around 2 billion yen with Kyoto Bank as the anchor LP (March 2017)

- The Aim of Kyoto-born ‘Shisaku’ Fund – The Challenge of Makers Boot Camp to Revolutionize Manufacturing (August 2017)

- The ‘MBC Shisaku Fund,’ which supports mass production prototyping, closed at over 2 billion yen / Strengthening support by building a supply network for startups (July 2018)

- Unleashing Japan’s Prototyping Power – Overcoming the ‘Valley of Death’ for Manufacturing startups (September 2018)

- Hardware is the Weapon with Which Japan Can Fight the World – The Challenge of Makers Boot Camp (November 2018)

- The lifeline of Japanese companies lies in ‘Supporting Manufacturing Worldwide’ (August 2019)

3rd Stage (2020-2023) – Establishment of Monozukuri Ventures and Boosting Operations in the US

Through our experiences with the first fund, we were overwhelmed by the sheer number and speed of startups in the US. When we established Darma Tech Labs, we wanted to challenge on a global scale, and in the first fund, we were expanding our business with Fab Foundry, which is based in NYC and supports hardware startups. Talks of integrating the two companies emerged due to having the same mission and vision. We both believe that startups can drive a better society and that Japan’s manufacturing industry can contribute more. Integration was not easy for small companies like us, let alone those in Japan and the US. Finally, we were able to make a start as Monozukuri Ventures (MZV) in 2020. The most discussed topic at that time was the philosophy (mission and vision) of MZV. “manufacturing is easy” came up at that time, indicating the society we aim to form. I love this phrase.

- Launch of ‘Monozukuri Ventures,’ Supporting Hardware Startups in Japan and US (January 2020)

- Survival Strategy for Japanese Manufacturing as Seen by ‘Monozukuri Ventures’ — Helping Startups Around the World Cross the ‘Valley of Death’ (March 2020)

Using this opportunity, we recruited more staff to accelerate our operations in the US. In addition to our base in NYC, we hired venture partners from the west coast, mainly in Silicon Valley. Also, we started strengthening our system in the Midwest, centered around Pittsburgh, where we had many investments from the first fund. When we talk about the east coast and the Midwest, we are often asked, “Why not the west coast?” The Midwest, including the Great Lakes, is actually a big manufacturing area. Many hardware and hard tech startups are born against this industrial backdrop, and it is attracting attention as an area where new manufacturing technologies are being born.

From the Rust Belt to One of the Leading Cities of Entrepreneurship: The Resurgence of Pittsburgh (June 2017)

HardwareCup Finals 2017 in Pittsburgh

We found that these new waves of manufacturing in the US could be very beneficial for Japanese manufacturing companies, so we established the second fund in January 2021. In addition to IoT, we expanded the investment area to include manufacturing technologies in the material and software areas. At the same time, we built a system to support business development, especially to support the expansion of US startups into Japan.

- Monozukuri Ventures in Kyoto forms a second fund of around 4 billion yen (February 2021)

- Monozukuri Ventures Final Closes Second Fund (September 2022)

We have invested in over 20 startups in Japan and the US in the second fund, and there are some cases of collaboration between US startups and Japanese companies. Arieca, a company based in Pittsburgh that develops semiconductor materials with excellent heat dissipation, was looking for a mass-production partner. We at MZV started looking for such a partner in Japan along with our financial support. And we were fortunate enough to get connected with Nissan Chemical Corporation. Since then, a manufacturing contract with Nissan Chemical has been concluded, and production has started.

Monozukuri Ventures makes additional investment in Arieca. Nissan Chemical, US 412 VF leads Series A (June 2022)

4th Stage (2023-) – Promotion of Open Innovation in Japan’s Manufacturing Industry

Lastly, I would like to talk about the future of MZV.

MZV has a strong image of prototyping support, but we realized that just prototyping support is not enough to achieve a society where “manufacturing is easy.” Through our experience and achievements, we have found that small-scale production (quickly and cheaply producing 1000 pieces) and business development (how to sell) are also big hurdles for startups.

Regarding small-scale production, we plan to create a base for small-scale production in the Umekoji area northwest of Kyoto Station in collaboration with local financial institutions and companies. This area is where the central wholesale market of Kyoto is located. But with the decrease in the market’s turnover, wholesalers have gone out of business, and vacant warehouses have increased. We are working to create a creative base using these empty warehouses, focusing on digital manufacturing and the like.

Possibilities as a Sanctuary of Innovation: What is the ‘Kyoto B-Side’ Umekoji Area? (December 2022)

As for the business development of startups, more and more Japanese manufacturing companies want to introduce new ideas and technologies from startups. Startups and Japanese manufacturing companies complement each other, and innovations can be born if we create a smooth pipeline between them.

The keyword is “open innovation in manufacturing.” We have also started the “Kyoto Acceleration Program which contributes to creating new businesses in large companies. By contributing to the construction of new businesses, we aim to achieve MZV’s vision of “manufacturing is easy.”

Japan’s Largest Cedar ‘Success Cedar’ in Ohtoyo Town, Kochi Prefecture (August 2022)

- The Next Move of Major US Tech Companies Underway Behind Large-scale Layoffs (March 2023)

- Misconception About Google’s Fight against ‘Innovation Dilemma’ (April 2023)(April 2023)

- Appendix: List of press releases during the DTL era

At Monozukuri Ventures, we introduce manufacturing and hardware industry trends from the perspective of a hardware-focused venture capital firm. If you’re interested, please sign up for our newsletter(JP).

Monozukuri Ventures CEO. Originally from Aichi Prefecture, I have lived in Kyoto for 17 years. I have always been involved in the startup scene, primarily in the Kansai region. Currently, I am taking on the challenge of urban development in the Umekoji area of Kyoto, creating a community where startups, artists, and creators can gather. As a father of two children, I am also doing my best in parenting!